Although the idea isn’t at all new, the idea of an “industrial metaverse” has gained substantial steam so far this year, with more companies embracing digital twins for their facility operations and technological leaps being made that directly benefit this particular space. This is still very much a nascent stage – some may even argue it hasn’t even reached the stage of being considered nascent – and so the main players may certainly change. That being said, right now it’s hard to argue against NVIDIA and Siemens being at the forefront of implementing these ideals of a digital representation of enterprise operations.

Broadly speaking, NVIDIA is most well-known for their place in the AI boom, a central location thanks to their chip manufacturing that has helped make them among the most valuable companies on the planet. That’s not all they do, though, and their Omniverse platform has proven invaluable to real-time visualization and simulation capabilities. Siemens, meanwhile, has their Xcelerator ecosystem for businesses looking to increase their digital footprint. Recently, the two platforms have been connected in a “deepened” collaboration, extending possibilities in the industrial metaverse realm.

Even more recently, Hannover Messe was held in Germany, an annual conference for innovation in the industrial space. Siemens, as one would expect, always has a large presence, and they were joined by NVIDIA this year to further speak to advancements in the industrial metaverse. As part of that initiative, they took part in a 30-minute live discussion, which can be watched back on LinkedIn. The moderated discussion featured Siemens President and CEO, Roland Busch, and VP of Omniverse and Simulation with NVIDIA, Rev Lebaredian.

The conversation started with a broader look at where industries are today in their industrial revolution, particularly using NVIDIA’s technology. Both Busch and Lebaredian noted how striking it is to walk around the event and seeing how quickly the industry has changed.

“You see the next level of technology we are bringing to our customers,” Busch said. “It’s getting more and more digital, and yet for our people at all the exhibitions, a little bit more complicated to explain what’s in there.”

Lebaredian had the same thoughts around the rapid digitalization in industry, and noted that this is only the second year NVIDIA has exhibited with Siemens. It’s quickly feeling like their technology clearly belongs, though. “Because it’s becoming more digital, people like me have a more natural place to participate here,” he said in opening remarks for the conversation.

As the talk went on, both speakers talked about how exactly AI would “transform the industry,” as people have so often said, and why the industrial metaverse is ultimately necessary. Busch responds by first talking broadly about why this idea of a digital representation of the real world is so important, telling the crowd that these efforts are “combining the real and digital worlds. In doing that, we can leverage the speed and power of software in making our hardware better.” He continued by saying AI and, more specifically, large language models, are the “boosters” for this effort, allowing humans to interact with these digital interfaces using natural language.

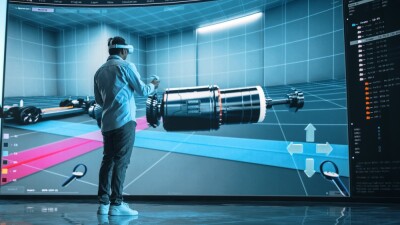

Speaking more directly to the industrial metaverse, both Busch and Lebaredian cautioned against conflating this idea with the more broad meaning of the metaverse, the social and gaming-based idea that overtook mainstream imagination for a fleeting moment. Many of those applications were based around fantastical worlds, rather than being a physics-based representation of a real-world entity. It’s that piece which is so important to this industrial metaverse idea.

“Once you have [the real world represented in a physics-based digital world], everything that we can do out here in the real world – all of the things that take time, material, energy, and money – we can do inside the digital world,” Lebaredian said. “We can design these things at a speed that would be impossible to do in the real world.”

Busch echoed many of these thoughts, particularly noting the importance that these representations are not just visual replications, but also behave like the real object. He says that those who want to utilize these digital twins in operations – which is essentially the point of a theoretical industrial metaverse – they need to be “comprehensive,” and also real-time. All of this is certainly going to take time, and he concedes that there are still hurdles to clear (synchronizing time stamps was one example given in the talk), but that we are on the right path.

One of the most interesting parts of the conversation was talking about real-world applications and how a workforce could potentially benefit from these innovations. This part of the discussion focused mostly on robotics, which is of course a major part of almost every large-scale manufacturing operation. They have been around for quite some time, but as Lebaredian points out they largely have not been “superintelligent,” and also “blind.” Essentially, they are just programmed to repeat the same action over and over again, which is helpful but also limiting.

Companies are starting to push the limits of what can be done with robotics, but this training can’t safely take place in the real world, at least at the beginning. Similarly to self-driving vehicles, it’s a conundrum of needing real-world conditions to train but needing to avoid the actual real world to keep surrounding people and things safe. This is one of the biggest impacts an industrial metaverse can have, as the physics-based representation can help train for a multitude of scenarios until it is safe to finish off the training in a real-world environment.

It’s also important, as Busch points out, that these digital representations are entirely photorealistic. He gives an example of a robotic tool that needs to grip a specific object. It’s important that, during training, the object is entirely photorealistic, including with the way light hits and reflects off of it. If those details weren’t built into the model during training, the real-world results will not be as desired.

Ultimately, as noted above, we’re still in the early stages of an industrial metaverse’s development, but this partnership between Siemens and NVIDIA is clearly helping to unlock some of these capabilities and workflows. And Lebaredian is extremely excited about what’s coming down the road. “What we’re doing now, as awesome and powerful as it is, it’s just a tiny bit of what’s about to come.”